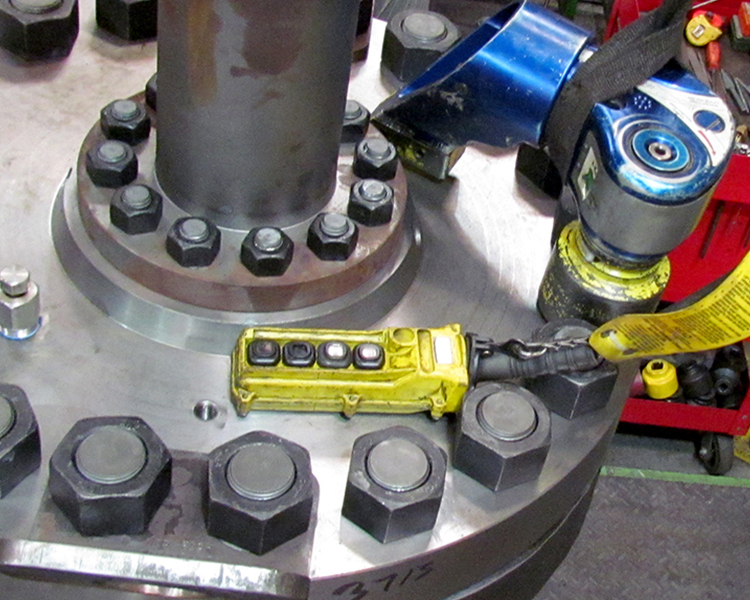

BOLT TORQUEING

- Torque is simply a measurement of the twisting force required to spin the nut up along the threads of a bolt.

- Torqueing provides the tension by the amount of rotational force they apply to the bolt.

- As the force is applied, the threading draws the nut face and bolt head closer together, stretching the bolt and creating the clamping force

This is the principle of bolt torqueing and it is the most common form of providing load to a bolt

- Equal torque distribution.

- Equal stress at every points.

- Lesser chance of leakage.

- Time optimization.

- Faster service.

- Fewer manpower utilization.

Neotight offers Bolt Torqueing solutions from 32 MM to 155 MM range.

- On call services

- AMC / ARC services

- Onetime services

- More than 100 machines readily available at our base to serve your requirements

- ATE-X certified machines

- Pneumatic / Electric torqueing power packs

- More than 10 years of operator's experience in the same field

- Skilled & educated professional engineering experts on site to serve you

Besides this, usage of uncontrolled methods for bolting will result in uneven stress distribution, hence we recommend going for Neotight's bolt torqueing solution for a leak free joint.

BOLT TENSIONING

- Bolt tensioning works by preloading the bolt and stretching it before the nut is tightened.

- The tensioner is clamped to the bolt’s threads and pushes against the flange in the surface being bolted.

- This provides a very consistent amount of stretch to the bolt, ensuring consistent bolt stretch and clamping force.

- Hence, to achieve an accurate & precise joint sealing load bolt tensioning is recommended.

- No damage to studs

- No damage to threads

- Direct load on flange

- High pressure machines

- Faster service when compared to torqueing

- Tightening with single effort

- On call services

- AMC / ARC services

- Onetime services

- More than 40 machines readily available at our base to serve your requirements

- ATE-X certified machines

- Pneumatic / Electric torqueing power packs

- More than 06 years of operator's experience in the same field

- Skilled & educated professional engineering experts on site to serve you

"Neotight offers Bolt Tensioning Solutions from 32 MM to 155 MM range"

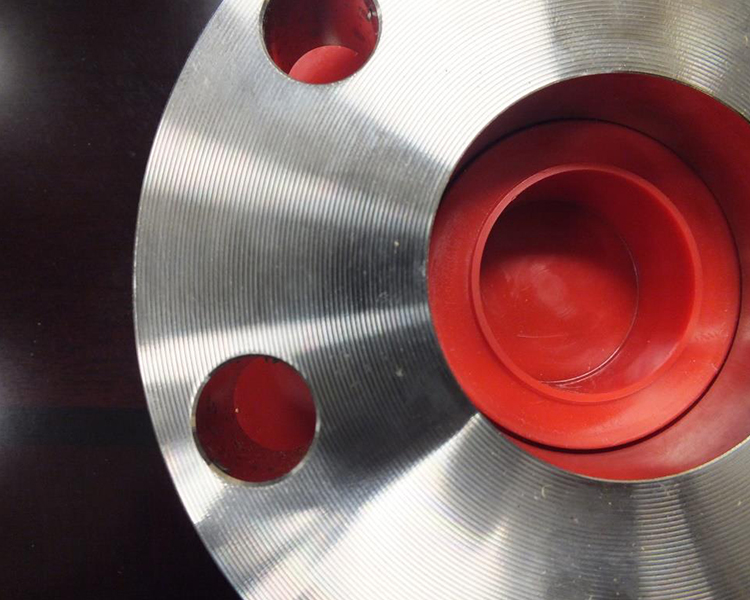

Flange Facing & Serration

- In case of dents on flange / gasket sitting area / damaged flange damaged RF sitting / misalignment of flange surface, flange facing would come to our customer's rescue.

- We have three types of machine set ups for machine fitment. Mirage & Climax machines are readily available with us to serve you beyond the satisfaction level.

- 0.02 micron will be the least surface finish quality with respect to our machine's output

- All types of serration are possible with our machines. 55 groves at 1 inch space can be done with respect to standards.

" Neotight offers Flange Facing & Serration solutions from 12’’ to 55’’ range. "

- On call services

- More than 3 machines readily available at our base to serve your requirements

- Pneumatic machines

- Single point facing tools

- 0-360-degree rotation tool post

- More than 12 years of operator's experience in the same field – operator’s

- Advanced techniques

- No heating at flange body

- Ability to fit anywhere

- 60 RPM speed at min feed

Manual Serration

- Manual serration machines are used for LPD / Valves / Flanges Exchangers & all type of equipment’s.

- Whenever small impurities / dents are present at flange surface, manual serration machines come in handy

- No power is needed for execution rather manpower movement becomes the source for that.

- Single point HSS tools will also provide the best groves in the shortest time possible and exchanger's serration can also be repaired within 40 minutes. exchanger’s serrations can be repaired.

" Neotight offers Manual Serration solutions from 0’’ to 100’’ range. "

- More than 20 machines readily available at our base to serve your requirements you with respect to requirements

- Single point serration tools

- 0-360-degree rotation tool post

- More than 5 years of operator's experience in the same field – operator’s

- Ability to fit anywhere

- No power source needed

- No hot work needed

- Can be operated by one person

- Fast, easy & qualitative output

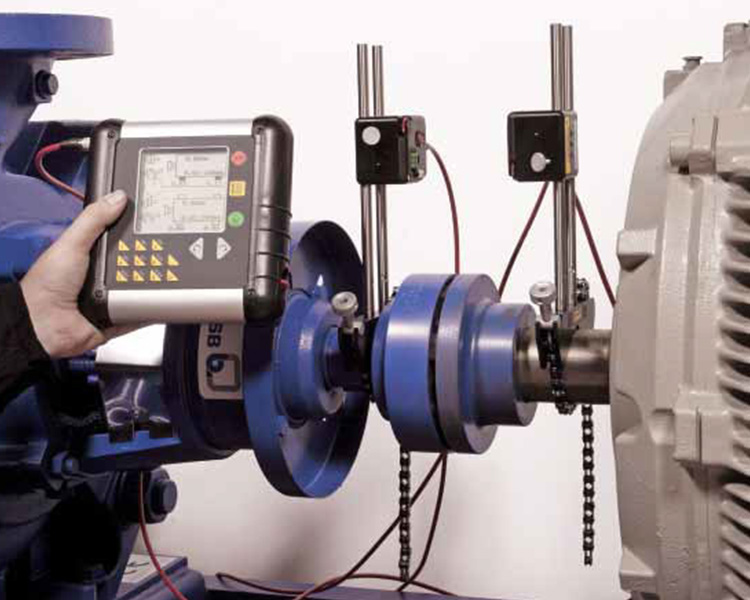

BLUE MATCHING - SOFT FOOT CORRECTION

- Due to vibrations/misalignment, inclined planes/variation the base flange & the pump flange aren't able to match surface

- Due to this, more vibration & noise are generated, hence to overcome this blue matching becomes the solution for that.

- We have skilled grinders & blue matching operators who can resolve these issues readily.

" Neotight offers Blue Matching solutions of up to 1 meter diameter. "

- More than 5 machines readily available at our base to serve your requirements

- Certified grinders

- Calibrated tools

- Surface plates

- Master plates

- Striate edges

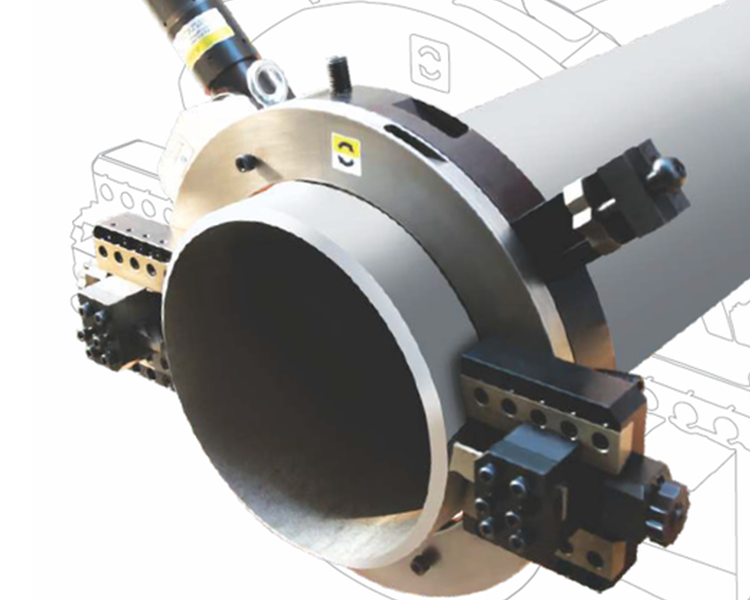

COLD CUTTING & CHEMFERING

- Whenever & wherever pipes/exchangers needs to be cut, our cold cutting machines are readily available to be deployed. Our machines can easily mount around the periphery of diameter

- Our machines ensures that no spark is generated and at the same time completes the cutting operation within a short period of time. cutting operations can complete.

- Our tools are designed to take the least amount of clearance and at the same time ensures that the cuts are both precise and accurate

" Neotight offers Cold Cutting & Beveling solutions from 2’’ to 56’’ range. "

- On call services

- More than 22 machines readily available at our base to serve your requirements

- Pneumatic machines

- HSS tools

- More than 6 years of operator's experience in the same field – operator’s

- Skilled & educated professional engineering experts on site to serve your requirements

- Standard SOP’s

- Accurate cutting

PROCESS SERVICES

- We provide pre-commissioning and maintenance related services on various process systems whether it is onshore oil and gas plant, offshore platform, petrochemical complex, refinery or power plant, we assist our customers for various process system related services

PRE-COMMISSIONING

- CHEMICAL CLEANING

- LUBE OIL FLUSHING

- HYDROTESTING

- AIR DRYING

- VACUUM DRYING

- N2 /HE LEAK TEST

- HYDROJETTING NITROGEN PURGE

MAINTENANCE

- CHEMICAL CLEANING

- LUBE OIL FLUSHING

- DECONTAMINATION

- NITROGEN PURGE

- BOLTING

- HYDRO JETTING

- TANK CLEANING

- DECRUDING/DE-GASSING

PIPELINE SERVICES

- We provide pre-commissioning and maintenance related services on various pipeline systems whether it is onshore, offshore or inter refinery pipelines, we assist our customers for various pigging and testing services.

PRE-COMMISSIONING

- CLEANING

- PIGGING

- HYDROTESTING

- DEWATERING

- DRYING

- VACUUM DRYING

- NITROGEN PURGE

MAINTENANCE

- CLEANING

- PIGGING

- DECRUDING

- DEGASSING

- GEL CLEANING

- CHEMICAL CLEANING

- NITROGEN PURGE